FIRST HYDROGEN BUS ROUTE IN FRANCE

François Bayrou, President of the community of Pau Béarn Pyrénées, made a public announcement about the creation of a “zero emission” bus route. For the first time in France, hydrogen will be used to power public transport.

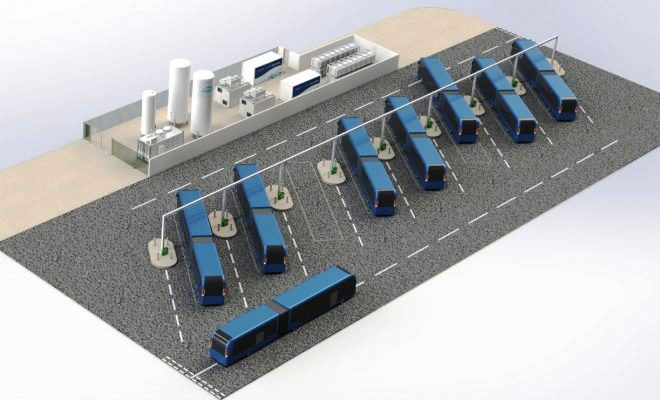

Fuelled by hydrogen from renewable sources, eight buses from the Rapid Bus Transit Service will be operating on the streets of Pau within two years, as part of a contract between Syndicat Mixte de Transports Urbains, Engie, Van Hool and ITM Power.

Renewable energy will be stored in the form of pressurized hydrogen and electricity will be produced on board the vehicle by a fuel cell, which does not emit any greenhouse gases or atmospheric pollutants, only water vapour. The buses will form an artery of the new transportation network designed by the City within its urban redevelopment project aimed at improving the perception and use of public spaces in a sustainable way.

The hydrogen fuel cell buses have considerable advantages, with a long driving range of 350 kms and rapid recharging in 10 minutes. Amid the various zero-emission bus technology options, fuel cells provide the highest level of operational flexibility and productivity for a bus operator. Other characteristics of the Rapid Bus Transit Service give an excellent experience for the traveller, ensuring comfort, safety, availability, information, high frequency with short waiting time and a predominantly dedicated bus lane. The Rapid Bus Transit Service is an effective alternative to the introduction of rail mode transport, such as the tramway.

This bus project is part of a policy for sustainable mobility and preservation of the living environment for Pau’s inhabitants. The Rapid Bus Transit Service is the core of a new mobility, which will provide an enhanced and sustainable quality of life, increasing economic and residential attractiveness.

The buses will be designed and manufactured by Van Hool, who are the European manufacturers with the most expertise in hydrogen mobility, with more than 50 fuel cell hydrogen buses already in operation. As a leader and innovator, Van Hool are developing an articulated 18-meter fuel cell bus model for the Rapid Bus Transit Service.

HYDROGEN INFRASTRUCTURE FOR THE RAPID BUS TRANSIT SERVICE

Engie, via its GNVERT subsidiary, which is responsible for the distribution of alternative fuels, will take charge of the construction and operation of the hydrogen refuelling station for the buses. The hydrogen will be produced on site by an ITM Power PEM electrolyser powered by local renewable electricity, thus ensuring completely decarbonised energy for propulsion. With this flagship project, the Engie Group is positioning itself as a key player in the energy revolution. It is promoting green growth by increasing the share of renewable energy in the French energy mix, improving air quality as well as contributing to the optimisation of transport networks. This zero emission solution, with no CO2 or other pollutants, such as fine particles, nitrogen oxides, etc., demonstrates the potential of making the transition to renewable energy, while offering the best service to Pau public transport users. Philippe Van Deven, Managing Director of GNVERT said: “This project demonstrates the technical and economic feasibility of green mobility, combining improvement of quality of life in urban areas with the high level of service expected from public transport.”

SHELL GENERATING HYDROGEN FROM RENEWABLES IN GERMANY

Shell has announced a joint project with ITM to install a 10MW electrolyser to produce  hydrogen at the Wesseling refinery site within the Rheinland Refinery Complex in Germany. With a capacity of ten megawatts, this would be the largest unit of its kind in Germany and the world’s largest PEM (Polymer Electrolyte Membrane) electrolyser.

hydrogen at the Wesseling refinery site within the Rheinland Refinery Complex in Germany. With a capacity of ten megawatts, this would be the largest unit of its kind in Germany and the world’s largest PEM (Polymer Electrolyte Membrane) electrolyser.

This electrolyser technology is also suitable for improving the stability of the electricity grid, which has a growing share of intermittent renewable energy sources from solar and wind. Today the refinery uses approximately 180,000 tons of hydrogen per year in their various plants. The hydrogen is currently produced as a by-product of the refining process or through natural gas reforming. Hydrogen can also be produced by electrolysis which uses electricity to split water into the base components of hydrogen and oxygen. Electrolysis using low-cost renewable electricity could be a key technology for potential CO2 free hydrogen production in the Shell Rheinland Refinery.

“The envisaged hydrogen electrolysis would be a step into the future – opening the door to many new development options,” said Dr. Thomas Zengerly, the General Manager for the Shell Rheinland Refinery. The hydrogen produced could be integrated into the refinery processes. The location will also allow the refinery to later expand its facilities to supply hydrogen to potential new customers outside the refinery. “Hydrogen is a promising technology, even beyond direct use as a cleaner fuel for transport. In the future, it is also expected to play a key role in integrating energy storage and power grid balancing, thus enabling a reliable and growing share of renewables in the energy system,” added Brian Davis, Vice President of Integrated Energy Solutions at Shell.

In transport, hydrogen is one of the fuels that can reduce CO2 emissions and improve air quality at the same time. Shell is taking part in various initiatives to encourage the adoption of hydrogen as a transport fuel. In Germany, they are working with the government and industry partners in a cross-sector joint venture called H2 Mobility Germany, which supports the development of a nationwide expansion of hydrogen refuelling stations. Outside Germany, Shell already has hydrogen stations in the UK and California.

HYDROGEN REFUELLING STATION DESIGNS FOR LAS VEGAS

ITM Power launched a series of large-scale refuelling station designs at Hydrogen + Fuel Cells North America, part of the SolarPower International Conference in Las Vegas. The large-scale refuelling station designs are based around electrolyser configurations of up to 50MW in size with the capability to produce up to 20 tonnes of hydrogen per day. This is in response to industry demand for larger scale industrial installations for refuelling heavy logistics vehicles, such as road haulage vehicles, ships and trains. In addition, governments are also focusing on these areas in the drive to reduce harmful emissions.

ITM Power CEO, Dr. Graham Cooley, said: “These new refuelling station designs are being launched in response to a dramatic increase in the number of enquiries for refuelling heavy logistics vehicles at large scale as the viability of hydrogen power continues to gather scale and momentum across a growing number of industrial applications. ITM Power is in a prime position to support these important transportation sectors as they plan their transition to a greener vehicle fleet to reduce emissions. Air quality and fossil fuel emissions are now a high priority for governments worldwide.”

Diesel vehicles produce large amounts of smog-forming nitrogen oxide and particulate matter. Diesel emissions in the logistics industry cause more than US$20 billion in health impacts each year, according to the American Lung Association. Transport emissions are expected to double by 2050 according to the OECD.

Diesel vehicles produce large amounts of smog-forming nitrogen oxide and particulate matter. Diesel emissions in the logistics industry cause more than US$20 billion in health impacts each year, according to the American Lung Association. Transport emissions are expected to double by 2050 according to the OECD.

In California, the freight system is the single largest contributor of diesel particulate matter and smog forming nitrogen-oxide emissions. The Los Angeles basin has the nation’s highest ozone pollution. At the ports of Los Angeles and Long Beach, up to $14 billion will be spent under a new clean-air plan to eliminate diesel vehicles and loading equipment by 2035 with zero and near-zero-emission technology.

In shipping, large ocean-going ships tend to use bunker fuel that can contain up to 3,500 times more sulphur than the diesel used to fuel passenger cars. Shipping now accounts for 13% of annual sulphur oxide emissions worldwide according to the International Maritime Organization. Shipping is also responsible for 15% of global NOx emissions, and 3% of CO2 emissions, which are expected to increase considerably in the next 30 years. In rail transport, diesel engines in enclosed railway stations pose a risk to passengers and workers, according to an independent study by the University of Cambridge. Particulate matter (PM 2.5), sulphur dioxide (SO2) and nitrogen dioxide (NO2) concentrations were also found to be much higher than on a busy nearby road.

UK HYDROGEN FOR TRANSPORT PROGRAMME

The UK Government’s Hydrogen for Transport Programme will provide up to £23m to increase the uptake of hydrogen fuel cell vehicles and grow the UK hydrogen refuelling infrastructure.

Dr Graham Cooley, said: “The Hydrogen for Transport Programme is a further demonstration of the UK Government’s commitment to developing a hydrogen infrastructure in the UK as part of its target to eliminate diesel and petrol from UK roads by 2040. We welcome this initiative but note the huge disparity between the funding for hydrogen infrastructure and the charging infrastructure for battery electric vehicles.”

The new Hydrogen for Transport Programme was launched in August 2017 by the Office for Low Emission Vehicles (OLEV) and will provide funding via an open competition for both hydrogen refuelling stations and hydrogen fuel cell vehicles. This will enable future expansion of both network and individual stations and, where possible, additional applications that require hydrogen, such as stationary applications. It will also develop the case for expansion of the hydrogen infrastructure through links to trains or ferries, or to renewable hydrogen sources. ITM expects significant growth in this sector and currently has over £40m contracts in the pipeline.

WORLD’S FIRST TIDAL-POWERED HYDROGEN

The European Marine Energy Centre has produced hydrogen gas using electricity generated from their tidal energy site at the Fall of Warness, Eday, Orkney. This is the first time that hydrogen has been created from tidal energy anywhere in the world. It demonstrates the potential for a clean replacement for polluting fuels. Scotrenewables’ and Tocardo’s turbines feed power into an onshore electrolyser supplied by ITM Power. The electrolyser uses the electricity to split water (H2O) into its component parts – hydrogen (H2) and oxygen (O2).

The electrolyser is housed in a standard 20 ft by 10 ft ISO container with hydrogen generation capacity of up to 220kg/24hours.

The 0.5MW polymer electrolyte membrane (PEM) electrolyser, comes with integrated compression and up to 500kg of hydrogen storage. The investment in hydrogen production capability has been made possible by funding of £3 million from the Scottish Government, made available through Highlands and Islands Enterprise.

Scottish Minister for Business, Innovation and Energy, Paul Wheelhouse, said: “The Scottish Government is pleased to be supporting this innovative project which will help to overcome grid constraints in the Orkney Islands by enabling the storage of excess tidal power generated and using that electricity to produce hydrogen. The project also adds to our growing understanding of the potential role of hydrogen in Scotland’s future energy system.”

Neil Kermode, Managing Director of the European Marine Energy Centre, said: “The electrolyser was set up to pilot the production of hydrogen fuel from tidal energy. Whilst the initial driver behind buying an electrolyser was to provide a storage solution to circumvent local grid constraints, the purchase has sparked off other pioneering projects around Orkney looking to use hydrogen in various means. So we’re now looking towards the development of a hydrogen economy in Orkney. One of the most promising uses of hydrogen is as a fuel for transport as it emits no carbon when it is consumed and, providing it’s generated by clean renewable energy sources, it becomes a carbon neutral fuel source. Therefore, we could see green hydrogen, over time, replace polluting fuels in our cars, vans and ferries.”

One of the projects that will be using the electrolyser is the Surf ‘n’ Turf Project which already obtains power from a 900kW Enercon wind turbine owned by the Eday community. The hydrogen will be transported to Kirkwall, where a fuel cell installed on the pier will convert the hydrogen back into electricity for use as auxiliary power for ferries when tied up overnight. The project is also developing a training programme with a view to green hydrogen eventually being used as a fuel source on the inter-island ferries.

Bryan Rendall, Director of Brian J Rendall Electrical Ltd said: “We are really looking forward to seeing more and more hydrogen infrastructure in Orkney to complement the renewable energy electrical infrastructure we have built out over the last 18 years. We are delighted to have worked with so many of the project partners including Eday Renewable Energy, the European Marine Energy Centre, ITM Power and Community Energy Scotland and to have had so much support from the people on Eday.” www.itm-power.com