With great sadness, it is reported that Jean Aldous, founder and Editor of Fuel Cell Power, died on 9th January 2024. From the 1970s, she and her late husband, Alan, were involved in the development of electric vehicles. Both were advocates for fuel cells and greatly admired Dr F.T. Bacon F.R.S who worked on alkaline fuel cells for most of his life and developed the first practical fuel cell. Jean first issued Fuel Cell Power in 2000 and the final copy was published online in Spring 2022.

Category: Uncategorized

Spring 2021 edition

Around the world organisations are changing to zero carbon energy obtained from renewable sources or recycled organic waste. Electrochemical energy conversion with fuel cells is two or three times more efficient than combustion and there are no other emissions of nitrogen oxides or particulate matter.

Fuel Cell Power Spring 2021 illustrates applications in double decker buses, trains, marine vessels, a passenger plane in local flight, cars, service vehicles, unmanned aerial vehicles (UAVs) and providing combined heat and power (CHP) for buildings and industry.

Engineers concerned about air pollution and climate change have been working for decades to make zero emission fuel cells available but there has been little interest from established industries which are backed by governments. There is now growing demand for cost effective zero emission energy systems both in advanced and developing countries and international programmes are essential to make fuel cells available.

Summer 2020 edition

Energy suppliers are inefficient in their use of finite resources and are responsible for air pollution and climate change. Fuel cells are two or three times more efficient than combustion and are increasingly powered by hydrogen from renewable sources or biofuels which at present are being wasted. Fuel cells are providing power for transport, buildings and industry.

The growing utilisation of cost effective zero emission fuel cells around the world is illustrated in the latest issue of Fuel Cell Power.

Summer 2019 edition

After decades of development work by engineers concerned about air pollution and climate change, there is now more support for the change from combustion to electrochemical conversion with fuel cells. Electrochemical conversion is very efficient and there are no harmful emissions. If natural gas or biofuels are utilised, fuel cells have been developed to separate the carbon dioxide and make it available for use by industry or agriculture.

There is now more investment in fuel cells powered by natural gas and renewable hydrogen, in order that countries can meet their targets under the Paris Agreement. Engineers have also developed advanced fuel cells powered by organic waste. Many communities, particularly in developing countries, cannot afford large scale energy infrastructures, but they have agricultural and forestry waste from which they could make net zero emission electricity, heat and transport fuel. As the waste is not burnt there are valuable residues, including organic fertiliser and potable water.

The latest issue of Fuel Cell Power outlines the role of fuel cells in stopping air pollution and meeting net zero targets for global warming gases.

The latest edition of FUEL CELL POWER is now available

The latest edition of FUEL CELL POWER is now available. The established manufacturers of different types of fuel cells are spreading their markets with clean energy for buildings, electric buses and the first trains.

Many fuel cells around the world are being powered by hydrogen obtained from renewable sources. Some of the high temperature fuel cells are powered by natural gas, but the electrochemical process does separate the carbon dioxide, which is being utilised as a refrigerant or as a fertiliser. The latest advance is the development of the ethanol fuel cell, which enables drivers to use a liquid fuel to replace diesel.

Riversimple, the developers of the hydrogen fuel cell powered Rasa car, are operating their first hydrogen refuelling station for local users of their vehicles. Cygnus Atratus is working with several partners in the transition from diesel fuel to ethanol powered fuel cells. These have no harmful emissions and using energy from waste is carbon neutral. Both companies are manufacturing vehicles which can be refurbished and recycled on a local basis.

The world’s first energy self-sufficient housing complex in Sweden is powered by solar PV and thermal panels. Long term energy storage as hydrogen ensures the availability of electricity and heat throughout the Swedish winter, with additional reserves for a fuel cell car. Sweden is also contributing to the EU’s Hydrogen Highway, with the first hydrogen refuelling station powered by onsite solar energy.

Reports from the presentations given at the 2018 International Hydrogen and Fuel Cell Conference in Birmingham are given, together with a note about the 15th event this year.

FUELCELL ENERGY GENERATING RENEWABLE HEAT AND POWER

POWER GENERATION AND BIOGAS TREATMENT SOLUTION FOR WASTEWATER

FuelCell Energy has announced that their SureSource 1500™ fuel cell power plant operating on Anaerobic Digester Gas has received certification under the California Air Resources Board (CARB 2013) distributed generation emission standards. This certification acknowledges the clean air profile of SureSource solutions, which are cheaper, provide cleaner air and are more sustainable.

Municipal wastewater treatment applications for the SureSource solution enable the municipality to outsource the operation and maintenance of the fuel cell power plant as well as biogas treatment. These are provided by FuelCell Energy’s proprietary technology for biogas treatment and fuel quality monitoring. The versatile SureSource solution can utilize on-site renewable biogas or directed biogas as a fuel source and is the only fuel cell or other type of power generation technology to gain CARB certification to the 2013 Waste Gas standard using on-site biogas.

SureSource power plants are uniquely suited for operation utilizing on-site biogas since the system is able to use the low-Btu gas without a reduction in power plant output, and the power plants produce usable thermal energy which can support the digester eration. Power produced by the system can be used on site or sold to the electric utility under tariffs such as California’s BioMAT feed-in tariff. A modification of the technology is available in which the power plant produces vehicle-grade renewable hydrogen in addition to power and heat, supporting the developing infrastructure for fuel cell vehicles.

“We have gained extensive experience working with a number of municipal water treatment facilities, leading to our industry-leading expertise with fuel blending as well as our own state-of-the-art gas treatment and impurity monitoring processes,” said Frank Wolak of FuelCell Energy.

SureSource™ power plants solve energy, environmental and business-related power generation challenges by providing ultra-clean, efficient and reliable distributed power generation. The fuel cells combine a fuel such as renewable biogas, directed biogas or clean natural gas with oxygen from the ambient air to efficiently produce ultra-clean electricity and usable high quality heat via an electrochemical process. Virtually no pollutants are emitted due to the absence of combustion.

Suresource™ fuel cells with anaerobic digester create clean

electricity and heat from renewable biogas

PROVIDING HEAT AND POWER FOR NRG ENERGY

FuelCell Energy has announced that the NRG Energy Center in Pittsburgh, Pennsylvania will host a fuel cell power plant under a U.S. Department of Energy contract. The power plant will deliver energy to the NRG Yield facility, which provides heating and cooling for more than six million square feet of commercial and residential facilities in Pittsburgh. NRG Yield owns a diversified portfolio of contracted renewable and conventional generation and thermal infrastructure assets in the United States. These include fossil fuel, solar and wind power generation facilities that have the capacity to support more than two million American homes and businesses.

Cliff Bashford, the General Manager of the NRG Energy Center said: “This project supports NRG Yield’s focus on identifying and integrating energy solutions that seek to improve efficiency, lower fuel consumption and costs, and reduce our environmental footprint. We’re pleased to participate, and to support Mayor Peduto’s vision of a smarter, cleaner and more innovative energy future for Pittsburgh.”

Chip Bottone, CEO FuelCell Energy, added: “We are leveraging our commercial experience with this new solution, including industry leading electrical efficiency plus thermal capabilities packaged in a design that installs quickly. While this application will be a demonstration of the use of our solid oxide fuel cell platform for efficient power generation, it is also being used in other programs as the basis for our energy storage technology, whereby the cells alternate between electrolysis and fuel cell operation. The cells produce hydrogen during electrolysis mode, which is later used to make power in fuel cell mode.”

FuelCell Energy’s SOFC power generation technology generates electrical efficiency of approximately 60%, plus usable heat, for combined heat and power (CHP) applications, resulting in total estimated thermal efficiency between 80% and 85%. The fuel cell plant hosted at the NRG facility will operate solely on natural gas, although the technology is fuel flexible, with the ability to utilize coal syngas, natural gas, on-site renewable biogas or directed biogas.

20 MEGAWATT FUEL CELL FOR KOREA SOUTHERN POWER

Fuel Cell Energy has announced a 20 megawatt fuel cell project with Korea Southern Power Company (KOSPO). The SureSource 3000™ power plants will cleanly produce electricity and thermal energy to support a district heating system. The facility is expected to be operational in 2018, illustrating the relatively rapid deployment of fuel cell parks. Ui Seob Shin of KOSPO said: “We are focused on providing reliable and clean energy to our customers and the clean and predictable power generation profile of fuel cells is consistent with meeting our objectives.”

Hanyang Industrial Development Company, a leading global construction company in Seoul, will provide the engineering, procurement and construction services for the project. FuelCell Energy is selling the 20 megawatts of fuel cell power plants and expects to operate and maintain the installation under a 20 year service agreement. Young Jin Park, Executive Director Infrastructure Division at Hanyang said: “Fuel Cell power plants have high power density, they do not use much land and we expect to install these fairly quickly, which is somewhat unique for megawatt-scale power generation.”

“This is the first fuel cell project for KOSPO and we are pleased that the value proposition of our SureSource solutions meets the exacting needs of one of Korea’s largest utilities,” said Chip Bottone. “Our multi-megawatt, scalable easy-to-site clean energy solutions are well suited for utility-scale applications such as this project.”

Fuel cells are addressing the energy, environmental and economic goals of Korea. High population density with limited land requires highly efficient and affordable power that can be located near where the power is used. The virtual lack of pollutants and low carbon footprint of fuel cells, combined with affordable economics and minimal space needs, have led to significant fuel cell adoption by Korean utilities and independent power producers. With high availability and capacity factors, fuel cell power plants make meaningful contributions to Renewable Portfolio Standard targets.

RESILIENT ENERGY FOR STRATEGIC MILITARY INSTALLATION

FuelCell Energy has finalized a power purchase agreement with the Connecticut Municipal Electric Energy Cooperative (CMEEC) for the long-term supply of power to the U.S. Navy Submarine Base in Groton, Connecticut. CMEEC is owned by six municipal utilities and will be acting through and working with Groton Utilities to implement the new power supply. FuelCell Energy will install and operate the fuel cell installation.

“This project asssures our customer, the U.S. Navy, of long-term cost effective power delivered on the Base to ensure power to critical infrastructure, and delivered cleanly,” said Drew Rankin, Chief Executive Officer, CMEEC. “The fuel cell plants will also be configured for grid-independent operation to ensure resilient power for critical Navy infrastructure.”

“Energy expenses are the single largest cost for Navy installations, reflecting about 28% of our shore budget,” said Capt. Paul Whitescarver, commanding officer of the submarine base. “These fuel cells serve as another milestone as the Base continues to pursue the future development of a micro-grid and enhance our power diversification, physical and energy security, and community collaboration.”

Two SureSource 4000TM power plants with total output of 7.4 megawatts will be located on the U.S. Submarine Base in Groton to supply an existing electrical substation. The fuel cell plant is part of a multifaceted plan by CMEEC to provide new power resources and support the desire of the Department of Defense to add resiliency and grid independence to key military installations.

RENEWABLE TRANSPORT FUEL PROJECT WITH TOYOTA

FuelCell Energy is collaborating with Toyota to provide renewable hydrogen from biogas which Toyota will purchase for vehicle fuelling. The hydrogen will be generated on-site from a multi-megawatt SureSource™ fuel cell power plant located at the Port of Long Beach in California. FuelCell Energy will install and operate the fuel cell power plant that will generate and supply 100% renewable hydrogen for Toyota’s fuel cell electric vehicles and its heavy duty fuel cell Class 8 Proof of Concept Truck. The fuel cell plant will simultaneously generate renewable power to be supplied to the grid under the California Bioenergy Market Adjustment Tariff (BioMAT) program. This fuel cell solution meets Toyota’s fuelling needs affordably and sustainably, while supporting the advancement of California’s hydrogen fuelling infrastructure and adhering to the state’s mandate for utilizing low-carbon and renewable sources.

Doug Murtha of Toyota said: “Fuelling our Proof of Concept Semi-Truck, as well as our Mirai fuel cell electric vehicles with 100% renewable hydrogen from this stationary fuel cell system is a major accomplishment, and a key step in building a sustainable hydrogen ecosystem to help power Port operations.”

“This is an innovative and replicable global model for building an affordable hydrogen infrastructure to generate renewable transportation fuel that facilitates the wider adoption of fuel cell electric cars, trucks and buses,” added Chip Bottone of FuelCell Energy. “We are pleased to provide Toyota with a flexible project structure that meets their needs both sustainably and economically.”

FuelCell Energy’s distributed hydrogen solution co-produces hydrogen and clean power from methane based fuels such as renewable biogas. The methane is reformed to hydrogen using water and heat produced by the fuel cell, resulting in clean hydrogen production without water consumption. The California Air Resources Board (CARB) certified a prospective pathway for hydrogen production with this technology fuelled by biogas. CARB’s team performed a complete Life Cycle Analysis on the system and determined that it has a negative carbon intensity, as the power and hydrogen generation process is carbon-neutral due to the use of renewable biogas and the fuel cell waste heat is used to feed the internal reformation reactions.

The multi-megawatt SureSource Hydrogen™ plant will be located at the Port of Long Beach, generating renewable hydrogen to fuel Toyota’s Mirai vehicles as they arrive at the Port.

It will also provide hydrogen for Toyota’s heavy-duty fuel cell Class 8 Proof of Concept Truck, which can be seen in operation at:

https://www.youtube.com/watch?v=IYjS622zll8

BALLARD FUEL CELLS FOR BUSES, TRUCKS AND POWER MANAGEMENT

BALLARD TO POWER FUEL CELL TRAM-BUSES WITH VAN HOOL IN PAU, FRANCE

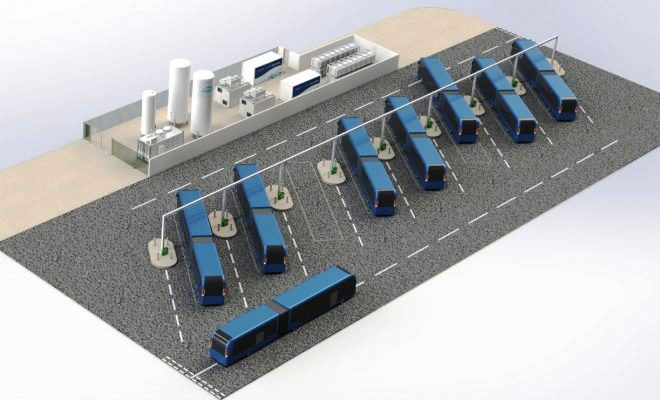

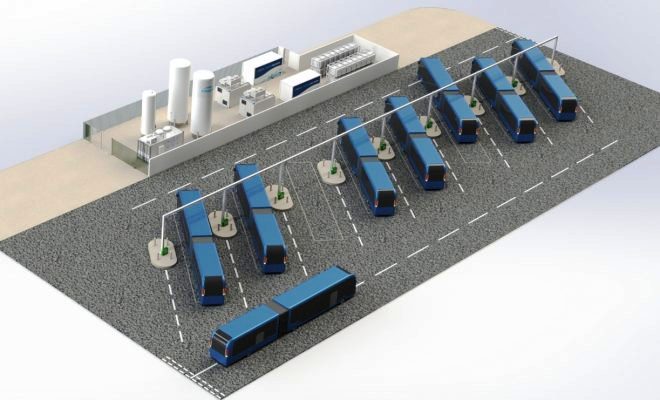

Ballard will be supplying 100-kilowatt fuel cells to power the eight tram-buses being built by Van Hool NV for delivery in Pau, France to the Syndicat Mixte de Transports Urbains.

This will be the first hydrogen bus route in France and the world’s first hydrogen tram-buses for a Bus Rapid Transit System. These clean energy hybrid tram-buses will use fuel cells for primary power and lithium batteries for additional power when needed, with the only emission being water vapour. Each tram-bus is over 18 meters long (over 60 feet), has capacity for 125 passengers and can operate more than 300 kilometers (185 miles) between hydrogen refuelling, which takes just 10 minutes to complete.

In addition to their environmental benefits, hybrid fuel cell tram-buses offer a number of important advantages, including: the highest level of operational flexibility and productivity; high levels of passenger comfort and safety; and lower cost than a traditional tram. Rob Campbell, Ballard Chief Commercial Officer, said that this is a further sign of the growing importance of zero-emission fuel cell solutions globally.

FUEL CELL BUS IN LONDON ACHIEVES 25,000 HOURS OF REVENUE OPERATION

A fuel cell bus powered by Ballard’s FCveloCity® fuel cells has achieved a new durability record, with more than 25,000 hours of revenue service. This is equivalent to operating a bus on a 14-hour daily schedule, 5-days per week for 6.9 years with no significant maintenance to the fuel cell stack, a core engine component.

The bus – and several others nearing the 25,000-hour operating threshold – are part of a Transport for London fleet of eight fuel cell buses carrying paying passengers on London’s Tower Gateway route since 2010. The buses were originally funded under the Clean Hydrogen in European Cities (CHIC) fuel cell bus programme.

Ballard’s seven generations of FCveloCity® fuel cell engines have been deployed in buses in 15 countries on five continents during the past 10 years. Over this period Ballard has worked with 13 bus manufacturers to develop a variety of fuel cell bus configurations that have been deployed in a wide range of climatic conditions and operated under a host of demanding duty cycles. Globally Ballard-powered fuel cell buses have now travelled cumulatively more than 11 million kilometers (6.8 million miles) in revenue service. Ballard is seeing increased market demand for FCveloCity® fuel cell engines of various sizes for use in a number of different vehicle types, including buses, trucks and rail.

SUNLINE TRANSIT AGENCY ORDER FIVE FUEL CELLS FOR BUSES IN CALIFORNIA

Ballard has received an order from SunLine Transit Agency for five FCveloCity® fuel cells to power clean energy buses in Palm Desert, California. The 150 kilowatt fuel cell engines are expected to be shipped in 2017. Ballard is partnering with ElDorado National, a key North American bus OEM, and BAE Systems.

This will double SunLine’s current fleet of fuel cell buses and allow it to offer an expanded transit service in Southern California. “We are very pleased with the continued progress in deployment of zero-emission mass transit alternatives in the U.S. market,” said Rob Campbell, Ballard’s Chief Commercial Officer. “Our partnership with SunLine, ElDorado National and BAE Systems puts Ballard at the forefront of North American fuel cell bus deployments and further adds momentum to the growing global trend toward clean energy buses and other heavy duty transit solutions.”

SunLine Transit Agency received funding from the Federal Transit Administration (FTA) to purchase and deploy the five hydrogen fuel cell electric buses. The program provides funding to transit agencies for capital acquisitions and leases of zero-emission and low-emission transit buses, including acquisition, construction and leasing of required infrastructure such as refuelling and maintenance facilities. The buses will use the previously deployed American Fuel Cell Bus configuration, which utilizes Ballard’s heavy duty fuel cell engine to provide primary power, in combination with BAE Systems’ electric propulsion and power management systems. There are currently 13 of these buses deployed with various transit agencies across North America, with another 10 on order including the five for SunLine.

BALLARD TO PARTNER WITH KENWORTH ON USE OF FUEL CELLS IN TRUCKS

Ballard’s 85-kilowatt fuel cell engine will power a hybrid class 8 drayage truck built by Kenworth Truck Company. The drayage truck is planned to haul shipping containers from the ports of Los Angeles and Long Beach to area warehouses and intermodal facilities.

The fuel cell engine in the Kenworth truck will be used to recharge onboard lithium-ion batteries, which power a dual-rotor electric motor to drive the rear tandem axle through a 4-speed automated transmission. The truck will have a battery-only range of approximately 30 miles, and onboard hydrogen fuel will provide sufficient range for a full day in regional haul applications.

Patrick Dean, Kenworth chief engineer said, “Within the next decade, hybrid-electric powertrains are expected to be required to satisfy emissions regulations in several major U.S. metropolitan areas. For example, California is considering regulations that will require zero-emission levels for port drayage trucks operating in specifically designated areas. We look forward to playing a leadership role to meet the opportunities and challenges ahead.”

Jason Hanlin, Director of Technology Development at the Center for Transportation and the Environment, noted: “The strength of this project comes from a team that is comprised of leaders in their respective fields – Kenworth for their heavy-duty truck design and manufacturing experience, BAE Systems for their powertrain integration and component supply experience, and Ballard for their extensive fuel cell supply experience. Working with this team on the technical development of a fuel cell drayage truck has been nothing short of impressive and inspiring.”

CEREMONIAL OPENING OF BALLARD’S CHINA JOINT VENTURE PRODUCTION FACILITY

A ceremonial opening event was held at the fuel cell stack joint venture operation in the City of Yunfu, in China. Ballard has a 10% interest in the joint venture – called Guangdong Synergy Ballard Hydrogen Power Co. Ltd. (JVCo) – together with partner Guangdong Nation Synergy Hydrogen Power Technology Co. Ltd. (Synergy). The fuel cell stacks manufactured by JVCo are expected to be used primarily in fuel cell engines assembled in China to provide propulsion power for zero-emission fuel cell electric buses and commercial vehicles in China.

At the ceremony Randy MacEwen, Ballard’s CEO, said “This landmark opening of our stack joint venture operation represents a critical part of our strategy to service the unprecedented level of market interest for fuel cell electric vehicles in heavy duty motive applications in China – the largest market in the world. Our strategy is to enable Ballard’s Chinese partners to rapidly achieve scale and significantly drive down product costs while also satisfying local content objectives for locally manufactured stacks and modules.”

The JVCo operation is currently ramping up to an annual production capacity of 6,000 FCvelocity®-9SSL fuel cell stacks by late 2017 and in the future is designed to achieve an annual production capacity of 20,000 fuel cell stacks. The operation includes certain advanced automation techniques. The joint venture transaction has an estimated minimum value to Ballard of $170 million over five years.

FLYH2 AEROSPACE

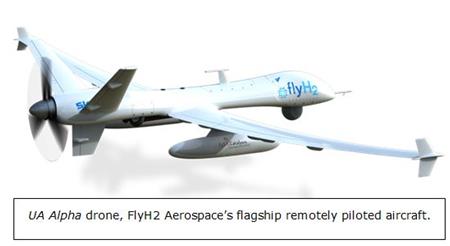

Ballard Power Company’s subsidiary, Protonex, has received an initial order for its fuel cell propulsion system from FlyH2 Aerospace, a South African-based developer of hydrogen fuel cell powered unmanned aerial vehicles (UAVs) for commercial applications.

FlyH2 plans to integrate the Protonex fuel cell system into all three of its aircraft currently in development. UA Plant is expected to be a 30 kilogram fuel cell-powered agricultural utility aircraft with 9-hour flight endurance. In agriculture, the use of unmanned aerial vehicles rather than conventional piloted aircraft, which sometimes operate as low as 150 feet above the ground, reduces the risk to pilots and also avoids noise abatement issues. In addition, the enhanced reliability of fuel cell engines further protects people and property on the ground.

UA Alpha will be a long-range, long-endurance survey and reconnaissance aircraft designed to carry advanced sensors.

Specifications include a wingspan of 8.2 meters (27 feet), maximum cruising altitude of 4,250 meters (14,000 feet) and flight distance of more than 600 kilometers (370 miles). Onboard sensors will survey environmental variables used in the management of fires, pollution, erosion, alien vegetation and plant diseases.

In a similar development, FlyH2’s third drone, the UA Gecko, is being designed to monitor physical infrastructure, including roads, bridges, pipelines and powerlines.

A fuel cell propulsion system allows for endurances comparable to an internal combustion engine, but with several added benefits. These include silent operation, increased reliability, lower vibration and less maintenance. The total cost of ownership is also expected to be lower and the aircraft will only require one fuel stop per day for all-day operations.

To support the integration of the Protonex fuel cell propulsion system into its UA Plant aircraft, FlyH2 has partnered with Epsilon Engineering, a South African engineering and manufacturing services provider. Project work is partially funded by the Government of South Africa as well as the South African agriculture industry.

Mark van Wyk, Co-Founder of FlyH2 Aerospace said, “Protonex systems bring with them unique new capabilities for our aircraft, allowing us to quickly fulfill our vision of producing high quality, rugged and reliable long-endurance electric unmanned aircraft.”

Dr. Paul Osenar, President of Protonex said, “FlyH2 has tremendous expertise in the design and development of drone systems, and recognizes the benefits offered by fuel cell propulsion. When combined with improved reliability and other advantages over internal combustion systems, fuel cells are proving to be a high value fit for UAVs. These will be the first civilian drones that we have powered, in addition to our work on military UAVs with several global aerospace customers.”

POWER MANAGEMENT KIT FOR US SOLDIERS

Ballard and Protonex have announced that the U.S. Army has received approval for its Mobile Soldier Power Program to start full rate production. This program includes a number of new devices focused on improving power and energy management on and around the soldier, including the Protonex’ Squad Power Manager Kit.

The Protonex kit is a tough, versatile and agile power management device, weighing less than a pound. It enables military forces to manage and prioritize power use for various electronic devices – including portable radios, GPS systems, medical equipment and computers – from any available power source. It has the ability to scavenge from vehicles, other batteries, solar panels and other energy sources, allowing military units to recharge essential batteries when resupply is unavailable or delayed. As a result, the U.S. Department of Defense and allied militaries have deployed more than 5,500 Protonex Squad Power Manager Kits through the limited production phase of the program.

“With the digitization of the battlefield, the U.S. military identified a capability gap in energy and power management for its increasing array of electronic devices,” said Paul Osenar, President of Protonex. “Our Squad Power Manager is one of the solutions that fill this gap, lightening the load of troops by eliminating many of the batteries, adapters and chargers they carry.” www.protonex.com.

WORLD’S FIRST PEM FUEL CELL USING

NON-PRECIOUS METAL CATALYST

Ballard Power Systems has been collaborating since 2013 with Nisshinbo Holdings, an environmental and energy company, to develop a non-precious metal catalyst for use in proton exchange membrane (PEM) fuel cells. Ballard has successfully incorporated the catalyst into a high performing catalyst layer under a Technology Solutions program and plans to launch a new 30-watt fuel cell stack product for commercial use later this year.

The FCgen®-1040 fuel cell stack using the non-precious metal will be a variant of Ballard’s micro fuel cell stack. It is designed for integration into ultra lightweight applications, such as laptop and cell phone chargers, and power devices for soldiers. Dr. Kevin Colbow, Ballard’s Vice President of Product Development said: “This stack represents a step-change in PEM fuel cell technology, with high performance at a reduced cost. Since platinum contributes 10% to 15% of the cost of a fuel cell stack today, we are very excited about the potential cost savings. Based on the success of this program we are interested in exploring its use for various commercial applications. Our goal is to ultimately implement lower-cost Non Precious Metal Catalyst based stacks into certain mobility applications, with an initial focus on materials handling. Blue-chip brands such as Walmart and Amazon have demonstrated the strong value proposition offered by current fuel cell-powered forklift trucks operating in high throughput distribution centers. The work done to date represents an important part of our strategy in Japan, where we are focused on breakthrough technology development with select partners”

HYDROGEN COUNCIL OUTLINES ROLE OF HYDROGEN AT COP23

HYDROGEN COULD CONTRIBUTE TO 20% OF CO2 EMISSIONS REDUCTION TARGETS

As global leaders gathered at the UN Climate Change meeting (COP 23) in Bonn, 18 key leaders in the industry, united in The Hydrogen Council coalition, came together to launch the first ever globally quantified vision of the role of hydrogen, developed with support from McKinsey. In addition to being a key pillar of the energy transition, the study shows that hydrogen has the potential to develop US $2.5tn of business, creating more than 30 million jobs by 2050.

Taking the Hydrogen Council’s vision for hydrogen to the next level, the study entitled Hydrogen, Scaling up outlines a comprehensive and quantified roadmap to scale deployment and it’s enabling impact on the energy transition.

Deployed at scale, hydrogen could account for almost one-fifth of total final energy consumed by 2050. This would reduce annual CO2 emissions by roughly 6 gigatons compared to today’s levels, and contribute roughly 20% of the abatement required to limit global warming to two degrees Celsius.

On the demand side, the Hydrogen Council sees the potential for hydrogen to power about 10 to 15 million cars and 500,000 trucks by 2030, with many uses in other sectors as well, such as industry processes and feedstocks, building heating and power, power generation and storage. Overall, the study predicts that the annual demand for hydrogen could increase tenfold by 2050 to almost 80 EJ in 2050 meeting 18% of total final energy demand in the 2050 two-degree scenario. At a time when global populations are expected to grow by two billion people by 2050, hydrogen technologies have the potential to create opportunities for sustainable economic growth.

“The world in the 21st century must transition to widespread low carbon energy use,” said Takeshi Uchiyamada, Chairman of Toyota Motor Corporation and co-chair of the Hydrogen Council. “Hydrogen is an indispensable resource to achieve this transition because it can be used to store and transport wind, solar and other renewable electricity to power transportation and many other things. The Hydrogen Council has identified seven roles for hydrogen, which is why we are encouraging governments and investors to give it a prominent role in their energy plans. The sooner we get the hydrogen economy going, the better, and we are all committed to making this a reality.”

Achieving such scale would require substantial investments; approximately US$20 to 25 billion annually for a total of about US$280 billion until 2030. Within the right regulatory framework – including long-term, stable coordination and incentive policies – the report considers that attracting these investments to scale the technology is feasible. The world already invests more than US$1.7 trillion in energy each year, including US$650 billion in oil and gas, US$300 billion in renewable electricity, and more than US$300 billion in the automotive industry.

“This study confirms the place of hydrogen as a central pillar in the energy transition, and encourages us in our support of its large-scale deployment. Hydrogen will be an unavoidable enabler for the energy transition in certain sectors and geographies. The sooner we make this happen the sooner we will be able to enjoy the needed benefits of Hydrogen at the service of our economies and our societies,” said Benoît Potier, Chairman and CEO, Air Liquide. “Solutions are technologically mature and industry players are committed. We need concerted stakeholder efforts to make this happen; leading this effort is the role of the Hydrogen Council.”

“When it comes to the future of mobility, zero emission technologies are an integral part of Daimler’s strategy. The benefits of the fuel cell are compelling: long range, short refuelling times and all that comes out of the “exhaust” is water. Moreover, the technology offers great opportunities for buses, other large commercial vehicles and not least stationary applications. With a steadily growing share of renewables, hydrogen will certainly play an increasingly important role in the overall energy system, making it increasingly attractive for the mobility sector as well”, says Jochen Hermann, Vice President e-Drive at Daimler AG.

http://www.hydrogencouncil.com

ITM POWER LEADING THE TRANSITION TO HYDROGEN AND FUEL CELLS

FIRST HYDROGEN BUS ROUTE IN FRANCE

François Bayrou, President of the community of Pau Béarn Pyrénées, made a public announcement about the creation of a “zero emission” bus route. For the first time in France, hydrogen will be used to power public transport.

Fuelled by hydrogen from renewable sources, eight buses from the Rapid Bus Transit Service will be operating on the streets of Pau within two years, as part of a contract between Syndicat Mixte de Transports Urbains, Engie, Van Hool and ITM Power.

Renewable energy will be stored in the form of pressurized hydrogen and electricity will be produced on board the vehicle by a fuel cell, which does not emit any greenhouse gases or atmospheric pollutants, only water vapour. The buses will form an artery of the new transportation network designed by the City within its urban redevelopment project aimed at improving the perception and use of public spaces in a sustainable way.

The hydrogen fuel cell buses have considerable advantages, with a long driving range of 350 kms and rapid recharging in 10 minutes. Amid the various zero-emission bus technology options, fuel cells provide the highest level of operational flexibility and productivity for a bus operator. Other characteristics of the Rapid Bus Transit Service give an excellent experience for the traveller, ensuring comfort, safety, availability, information, high frequency with short waiting time and a predominantly dedicated bus lane. The Rapid Bus Transit Service is an effective alternative to the introduction of rail mode transport, such as the tramway.

This bus project is part of a policy for sustainable mobility and preservation of the living environment for Pau’s inhabitants. The Rapid Bus Transit Service is the core of a new mobility, which will provide an enhanced and sustainable quality of life, increasing economic and residential attractiveness.

The buses will be designed and manufactured by Van Hool, who are the European manufacturers with the most expertise in hydrogen mobility, with more than 50 fuel cell hydrogen buses already in operation. As a leader and innovator, Van Hool are developing an articulated 18-meter fuel cell bus model for the Rapid Bus Transit Service.

HYDROGEN INFRASTRUCTURE FOR THE RAPID BUS TRANSIT SERVICE

Engie, via its GNVERT subsidiary, which is responsible for the distribution of alternative fuels, will take charge of the construction and operation of the hydrogen refuelling station for the buses. The hydrogen will be produced on site by an ITM Power PEM electrolyser powered by local renewable electricity, thus ensuring completely decarbonised energy for propulsion. With this flagship project, the Engie Group is positioning itself as a key player in the energy revolution. It is promoting green growth by increasing the share of renewable energy in the French energy mix, improving air quality as well as contributing to the optimisation of transport networks. This zero emission solution, with no CO2 or other pollutants, such as fine particles, nitrogen oxides, etc., demonstrates the potential of making the transition to renewable energy, while offering the best service to Pau public transport users. Philippe Van Deven, Managing Director of GNVERT said: “This project demonstrates the technical and economic feasibility of green mobility, combining improvement of quality of life in urban areas with the high level of service expected from public transport.”

SHELL GENERATING HYDROGEN FROM RENEWABLES IN GERMANY

Shell has announced a joint project with ITM to install a 10MW electrolyser to produce  hydrogen at the Wesseling refinery site within the Rheinland Refinery Complex in Germany. With a capacity of ten megawatts, this would be the largest unit of its kind in Germany and the world’s largest PEM (Polymer Electrolyte Membrane) electrolyser.

hydrogen at the Wesseling refinery site within the Rheinland Refinery Complex in Germany. With a capacity of ten megawatts, this would be the largest unit of its kind in Germany and the world’s largest PEM (Polymer Electrolyte Membrane) electrolyser.

This electrolyser technology is also suitable for improving the stability of the electricity grid, which has a growing share of intermittent renewable energy sources from solar and wind. Today the refinery uses approximately 180,000 tons of hydrogen per year in their various plants. The hydrogen is currently produced as a by-product of the refining process or through natural gas reforming. Hydrogen can also be produced by electrolysis which uses electricity to split water into the base components of hydrogen and oxygen. Electrolysis using low-cost renewable electricity could be a key technology for potential CO2 free hydrogen production in the Shell Rheinland Refinery.

“The envisaged hydrogen electrolysis would be a step into the future – opening the door to many new development options,” said Dr. Thomas Zengerly, the General Manager for the Shell Rheinland Refinery. The hydrogen produced could be integrated into the refinery processes. The location will also allow the refinery to later expand its facilities to supply hydrogen to potential new customers outside the refinery. “Hydrogen is a promising technology, even beyond direct use as a cleaner fuel for transport. In the future, it is also expected to play a key role in integrating energy storage and power grid balancing, thus enabling a reliable and growing share of renewables in the energy system,” added Brian Davis, Vice President of Integrated Energy Solutions at Shell.

In transport, hydrogen is one of the fuels that can reduce CO2 emissions and improve air quality at the same time. Shell is taking part in various initiatives to encourage the adoption of hydrogen as a transport fuel. In Germany, they are working with the government and industry partners in a cross-sector joint venture called H2 Mobility Germany, which supports the development of a nationwide expansion of hydrogen refuelling stations. Outside Germany, Shell already has hydrogen stations in the UK and California.

HYDROGEN REFUELLING STATION DESIGNS FOR LAS VEGAS

ITM Power launched a series of large-scale refuelling station designs at Hydrogen + Fuel Cells North America, part of the SolarPower International Conference in Las Vegas. The large-scale refuelling station designs are based around electrolyser configurations of up to 50MW in size with the capability to produce up to 20 tonnes of hydrogen per day. This is in response to industry demand for larger scale industrial installations for refuelling heavy logistics vehicles, such as road haulage vehicles, ships and trains. In addition, governments are also focusing on these areas in the drive to reduce harmful emissions.

ITM Power CEO, Dr. Graham Cooley, said: “These new refuelling station designs are being launched in response to a dramatic increase in the number of enquiries for refuelling heavy logistics vehicles at large scale as the viability of hydrogen power continues to gather scale and momentum across a growing number of industrial applications. ITM Power is in a prime position to support these important transportation sectors as they plan their transition to a greener vehicle fleet to reduce emissions. Air quality and fossil fuel emissions are now a high priority for governments worldwide.”

Diesel vehicles produce large amounts of smog-forming nitrogen oxide and particulate matter. Diesel emissions in the logistics industry cause more than US$20 billion in health impacts each year, according to the American Lung Association. Transport emissions are expected to double by 2050 according to the OECD.

Diesel vehicles produce large amounts of smog-forming nitrogen oxide and particulate matter. Diesel emissions in the logistics industry cause more than US$20 billion in health impacts each year, according to the American Lung Association. Transport emissions are expected to double by 2050 according to the OECD.

In California, the freight system is the single largest contributor of diesel particulate matter and smog forming nitrogen-oxide emissions. The Los Angeles basin has the nation’s highest ozone pollution. At the ports of Los Angeles and Long Beach, up to $14 billion will be spent under a new clean-air plan to eliminate diesel vehicles and loading equipment by 2035 with zero and near-zero-emission technology.

In shipping, large ocean-going ships tend to use bunker fuel that can contain up to 3,500 times more sulphur than the diesel used to fuel passenger cars. Shipping now accounts for 13% of annual sulphur oxide emissions worldwide according to the International Maritime Organization. Shipping is also responsible for 15% of global NOx emissions, and 3% of CO2 emissions, which are expected to increase considerably in the next 30 years. In rail transport, diesel engines in enclosed railway stations pose a risk to passengers and workers, according to an independent study by the University of Cambridge. Particulate matter (PM 2.5), sulphur dioxide (SO2) and nitrogen dioxide (NO2) concentrations were also found to be much higher than on a busy nearby road.

UK HYDROGEN FOR TRANSPORT PROGRAMME

The UK Government’s Hydrogen for Transport Programme will provide up to £23m to increase the uptake of hydrogen fuel cell vehicles and grow the UK hydrogen refuelling infrastructure.

Dr Graham Cooley, said: “The Hydrogen for Transport Programme is a further demonstration of the UK Government’s commitment to developing a hydrogen infrastructure in the UK as part of its target to eliminate diesel and petrol from UK roads by 2040. We welcome this initiative but note the huge disparity between the funding for hydrogen infrastructure and the charging infrastructure for battery electric vehicles.”

The new Hydrogen for Transport Programme was launched in August 2017 by the Office for Low Emission Vehicles (OLEV) and will provide funding via an open competition for both hydrogen refuelling stations and hydrogen fuel cell vehicles. This will enable future expansion of both network and individual stations and, where possible, additional applications that require hydrogen, such as stationary applications. It will also develop the case for expansion of the hydrogen infrastructure through links to trains or ferries, or to renewable hydrogen sources. ITM expects significant growth in this sector and currently has over £40m contracts in the pipeline.

WORLD’S FIRST TIDAL-POWERED HYDROGEN

The European Marine Energy Centre has produced hydrogen gas using electricity generated from their tidal energy site at the Fall of Warness, Eday, Orkney. This is the first time that hydrogen has been created from tidal energy anywhere in the world. It demonstrates the potential for a clean replacement for polluting fuels. Scotrenewables’ and Tocardo’s turbines feed power into an onshore electrolyser supplied by ITM Power. The electrolyser uses the electricity to split water (H2O) into its component parts – hydrogen (H2) and oxygen (O2).

The electrolyser is housed in a standard 20 ft by 10 ft ISO container with hydrogen generation capacity of up to 220kg/24hours.

The 0.5MW polymer electrolyte membrane (PEM) electrolyser, comes with integrated compression and up to 500kg of hydrogen storage. The investment in hydrogen production capability has been made possible by funding of £3 million from the Scottish Government, made available through Highlands and Islands Enterprise.

Scottish Minister for Business, Innovation and Energy, Paul Wheelhouse, said: “The Scottish Government is pleased to be supporting this innovative project which will help to overcome grid constraints in the Orkney Islands by enabling the storage of excess tidal power generated and using that electricity to produce hydrogen. The project also adds to our growing understanding of the potential role of hydrogen in Scotland’s future energy system.”

Neil Kermode, Managing Director of the European Marine Energy Centre, said: “The electrolyser was set up to pilot the production of hydrogen fuel from tidal energy. Whilst the initial driver behind buying an electrolyser was to provide a storage solution to circumvent local grid constraints, the purchase has sparked off other pioneering projects around Orkney looking to use hydrogen in various means. So we’re now looking towards the development of a hydrogen economy in Orkney. One of the most promising uses of hydrogen is as a fuel for transport as it emits no carbon when it is consumed and, providing it’s generated by clean renewable energy sources, it becomes a carbon neutral fuel source. Therefore, we could see green hydrogen, over time, replace polluting fuels in our cars, vans and ferries.”

One of the projects that will be using the electrolyser is the Surf ‘n’ Turf Project which already obtains power from a 900kW Enercon wind turbine owned by the Eday community. The hydrogen will be transported to Kirkwall, where a fuel cell installed on the pier will convert the hydrogen back into electricity for use as auxiliary power for ferries when tied up overnight. The project is also developing a training programme with a view to green hydrogen eventually being used as a fuel source on the inter-island ferries.

Bryan Rendall, Director of Brian J Rendall Electrical Ltd said: “We are really looking forward to seeing more and more hydrogen infrastructure in Orkney to complement the renewable energy electrical infrastructure we have built out over the last 18 years. We are delighted to have worked with so many of the project partners including Eday Renewable Energy, the European Marine Energy Centre, ITM Power and Community Energy Scotland and to have had so much support from the people on Eday.” www.itm-power.com

FUEL CELL POWER SUMMER 2017

The change from fossil fuels to renewable energy will require energy storage. It has taken hundreds of millions of years for the Earth to convert sunlight to the storable oil and gases which power buildings, industry and transport. Fuel cells powered by hydrogen and ethanol can provide a cost effective alternative. The electrochemical process does not have harmful emissions of nitrogen and sulphur oxides nor the particulates produced by combustion engines. Pure water is the only emission of fuel cells powered by hydrogen and oxygen.

The use of fuel cells powered by renewable energy can help to meet stringent climate change targets. Hydrogen can be obtained by the electrolysis of water when the available wind or solar power exceeds demand.

Huge amounts of energy are also available from household, industrial, agricultural and forestry waste, which can be converted to ethanol. Ethanol from this source is carbon neutral as no additional CO2 is added to the atmosphere or the oceans. The electrochemical process can also separate the carbon dioxide emitted by fuel cells using air or a hydrocarbon fuel. This can then be recycled in stationary applications and used as a growth enhancer or to form synthetic natural gas.

It is now possible to generate your own electricity and heat on site using indigenous fuels, with zero emissions. The fuel cell systems can be utilised alongside intermittent wind or solar power to store energy for when it is needed. Waste is also a low cost source of renewable energy for communities and industries.

Fuel Cell Power outlines the key to improving the environment as well as economic performance. It is freely available to download.